ALKA S.r.l.

Registered office: Via Teodoro Frizzoni 19 - 24121 Bergamo - Office: Via Molino Baertsch, 4 - 24124 Bergamo

Tel. +39 035 664881, Cell. +39 335 355569 - E-mail: info@alka-srl.com , PEC postmaster@pec.alka-srl.com

Bergamo Business Register, EORI, Tax Code and VAT No. IT02515810162 - Recipient code T04ZHR3

BG050196 mechanographic number, REA: BG 300962, Share capital €10,400.00 fully paid up.

Proven effectiveness and experience

A solution aimed at companies and professionals in the sector and can be used in various fields.

With ALKA Pro-Clean it is possible to degrease, lubricate, and disinfect, with extreme effectiveness, in short times, with minimal costs and using, only if necessary, very small amounts of chemical product. It is also possible to remove processing residues (e.g. cutting, welding, etc). It can also be used to perform product recovery in dosing pipes or as a tool for maintenance and, last but not least, quality control on new pipes.

Main advantages:

- Extremely fast and economical system

- Excellent for quality control and selection of new pipe suppliers

- Cleaning power superior to techniques with compressed air, washing or flushing

- Can be used for ordinary and preventive maintenance operations

- Can be used on pipes with bends (even 90°), fittings, T-junctions, ball valves, diameter changes

- Can be used on rigid or flexible pipes, compatible with any material (steel, copper, titanium, rubber, pvc, etc...)

- Great savings on chemicals and their disposal costs

New Pipes

For new pipe manufacturers (both bars and coils), this system allows for a drastic increase in the quality of the finished product as it can be used for the removal of cutting chips, soot, or for the removal of product residue following pickling which, if not removed, leaves a greasy deposit on the bottom of the tube, particularly difficult to remove later for the end customer during drying. Ideal for quality control of new pipes on arrival.

Hydraulics - Pneumatics

In hydraulic pipes, both flexible and rigid, it is essential to have no residues of any kind inside; even the smallest particles suspended in the oil can damage pumps, valves, or cause premature saturation of the filters. This system allows you to check and remove all residues present before testing, from cutting chips to rubber dust, also allowing you to verify the correct mixture and vulcanization of flexible pipes before their actual use; this also helps to speed up the start-up phase of the system.

Automotive - Railway - Aero - Naval

These are sectors where interest is shown at 360°, since on every machine there are various types of devices that work thanks to systems and pipes of various kinds, all of which require a high degree of cleanliness. From hydraulic and pneumatic handling systems, to sanitary piping, air conditioning, fuel injection pipes, braking systems, power steering, etc...This system makes it possible to carry out a strict but rapid quality control on the purchased pipes, thus ensuring a high and homogeneous quality standard, achieving maximum reliability and therefore also maximum safety.

Process plants: Food - Chemical - Medical - Cosmetic

The main advantage in this field is the reduction of waste, having the possibility to carry out, at the end of the various production cycles, the product recovery of what remains inside the pipes before having to perform the washing.

In this way, it is possible to recover significant quantities of good and sellable product and at the same time carry out a mechanical pre-wash that allows you to more effectively remove any product residues stuck to the walls or in the bends of the system. The system can also be used for the sanitization of the pipes, soaking the projectiles with disinfectant products, combining mechanical and chemical action.

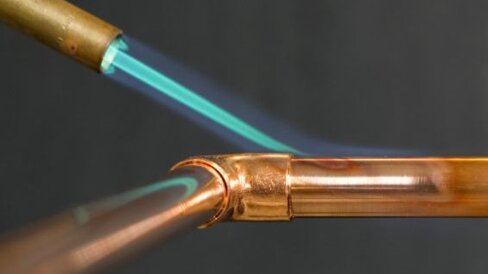

Air Conditioning - Thermohydraulics - Plant Engineering - Technical Gases

Before commissioning new pipes may contain inside them production residues such as grease or soot that can contaminate the product for which the system is intended, but also dangerous fragments attached to the walls that often do not come off immediately with washing by fluids or compressed air, but only in subsequent phases of use damaging the most delicate components of the system.

It is possible to carry out degreasing operations, for example on piping for technical gases (oxygen, hydrogen, nitrogen, argon) or air conditioning.

Maintenance

In industrial maintenance, there are many cases in which this system proves to be incredibly useful and efficient. Depending on the type of residues to be removed, it is possible to achieve results with speed and an economic commitment that are absolutely unrivaled compared to traditional techniques.

It is possible to intervene on plants of various shapes, without the need for disassembly or for cleaning heat exchangers, both coil and shell and tube, including U-tube types.